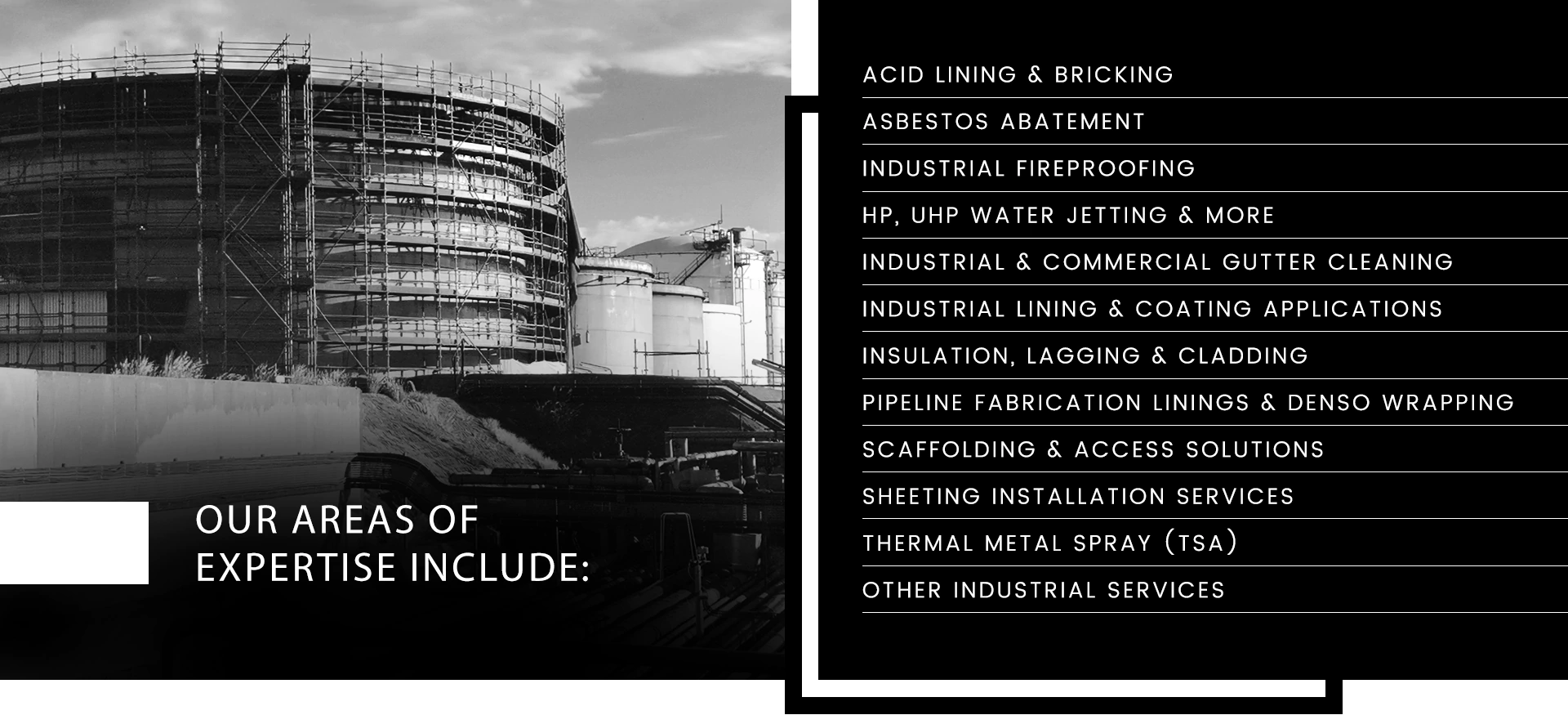

Wire Arc Spraying (Thermal Metal Spraying) constitutes a prevalent and commercially employed thermal spraying technique, particularly favored for the creation of coatings on various structural materials.

In this method, a pair of consumable metal wires, typically sharing the same composition, are meticulously fed into a spray gun at a consistent and synchronized velocity. These wires are endowed with opposing electrical charges, setting the stage for a controlled interaction.

Upon contact, the wires undergo electrical and thermal stimulation due to their contrasting polarities, culminating in their fusion at the melting point. This molten amalgamation is subsequently propelled onto a metallic substrate through the application of compressed air, ultimately resulting in the formation of a resilient and functional coating layer.

The inherent advantages of Wire Arc Spraying are manifold, chief among them being the bestowal of protection against the rigors of erosion, wear, and elevated temperatures. This technique thus emerges as an indispensable solution for fortifying and enhancing the durability of substrates in a myriad of applications.

Thermal Metal Spraying (Wire Arc Spraying)

Demonstration Video

Thermal Metal Spraying (Wire Arc Spraying)

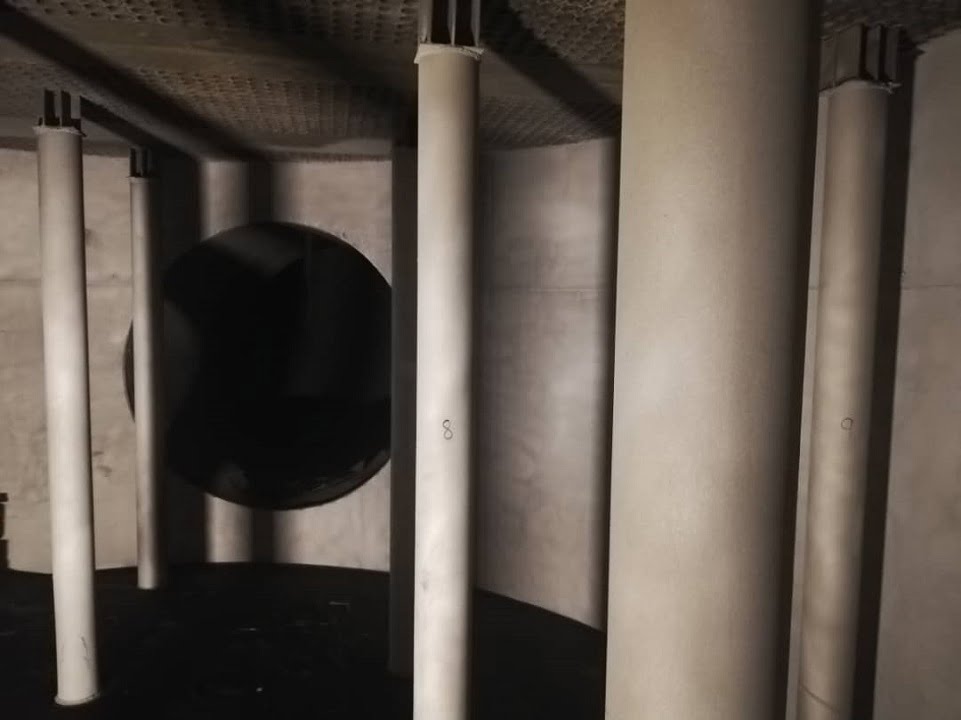

After Implimentation

Type of Protection

Metallic coatings offer 2 main types of protection:

Galvanic Protection

Barrier Protection

The combination of Barrier and Galvanic protection is unmatched in terms of:

Application

Cost

Versatility

No Curing Period

Cold Weather Friendly

It is a very effective way of protecting metals from deterioration due to corrosion.

Barrier Protection

- An impervious barrier that prevents moisture intrusion is formed when a metallic coating (ex. Zinc) is applied to the substrate.

- This results in suboptimal conditions for corrosion, as one of the essential components needed, the electrolyte (water), is removed from the equation and therefore, oxidation cannot occur.

Galvanic Protection

- Wire Arc Spraying provides corrosion protection through sacrificial galvanic action.

- The “coating” will provide protection to the substrate and will act as a sacrificial anode. It will give off electrons and sacrifice themselves for the substrate.

- The metallic coating corrodes in stead of the substrate, thus acting as a sacrificial coating and sparing the substrate in the process.

Advantages of Thermal Metal Spray (TSA)

Thermal Metal Spray offers numerous advantages that make it a preferred corrosion protection system:

- Quick Drying: TSA dries on impact, eliminating the need for curing time between coatings.

- Versatility: It can be applied on or off-site for new and existing plant equipment.

- Minimal Distortion: The TSA process does not cause distortion due to heat transfer, ensuring the integrity of the treated assets.

- High-Temperature Applications: TSA can be applied in high-temperature environments exceeding 200°C.

- Cathodic Protection: TSA provides cathodic protection to difficult-to-reach or damaged areas, such as pipe supports.

- Galvanizing Repair: It can serve as a repair procedure for galvanizing, irrespective of the size of the galvanizing bath.

- Extended Asset Life: TSA prolongs the life of your plant equipment, reducing maintenance frequency and associated costs.

If you have any questions or require TSA services for your upcoming projects, do not hesitate to get in touch with our expert team. We are here to ensure that your assets receive the best possible corrosion protection, enhancing their lifespan and minimizing maintenance costs.

Don’t compromise on quality and reliability. Choose Hemera Projects for unrivalled Thermal Metal Spray services.

Our team of highly skilled, professional and experienced staff, offer new and existing clients with an unparalleled level of expertise, knowledge and service.